Water News Europe

•

31st July 2023

The Advantages of On-Site Hydrogen Peroxide Generation Over On-Site Chlorine Generation

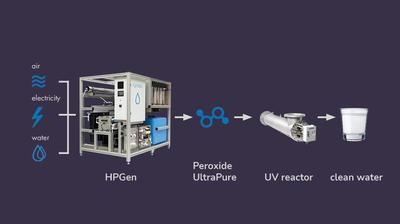

Hydrogen peroxide (H2O2) and chlorine are potent oxidizing agents used extensively across a myriad of industrial applications, including water treatment, disinfection processes, and bleaching in pulp and paper industries. Traditionally, these oxidizers are manufactured off-site and delivered to the user’s location. This traditional supply chain poses several challenges, including high transportation costs, storage difficulties, and potential safety risks. Recent advancements in technology, however, have made it feasible to produce these oxidizing agents on-site, leading to reduced costs and increased safety. Of these two options, on-site hydrogen peroxide generation, particularly by companies using no chemical inputs like HPNow, has shown promise in offering numerous advantages over on-site chlorine generation.